R&D

Engine and Transmission Systems Group

The Engine and Powertrain Systems Group, which operates under TÜBİTAK RUTE Alternative Energy Technologies Department, carries out design, analysis, calibration, testing and verification studies of high-power internal combustion engines of strategic importance for our country, and carries out R&D activities on the development of power transmission systems for railway, marine and land vehicles. It carries out pioneering studies for the development of environmentally friendly, highly efficient and carbon-neutral engines.

R&D

Purposes and Objectives

Purposes

- To develop IYM and power transmission systems that meet the needs of our stakeholders,

- Original and all intellectual property rights belong to our country,

- Produced with a modular structure and domestic resources,

- Environmentally friendly, efficient, and user-friendly.

Objectives

- To ensure the independence of our country, especially in the field of high-power ICE design, and to realize the production of strategic products in the railway and marine sectors,

- To contribute to our country's net zero targets with environmentally friendly, efficient and innovative technologies and to ensure that this target is achieved with domestic and national resources,

- To design and manufacture power systems for TCDD's existing diesel-electric locomotives with innovative traction systems.

Working Areas

- High Power (>1,000 hp) Diesel Internal Combustion Engines (ICE)

- ICE Modeling and Model Validation

- ICE Combustion Concepts and Fuel Injection Strategy Development

- Computational Fluid Dynamics (CFD), Combustion, and Structural Analyses

- ICE Design and Generation of Production Files

- ICE Parts Supply and Production Network

- ICE Assembly

- ICE Performance and Emission Calibration

- Hydrogen/Ammonia Fueled Internal Combustion Engines

- Development of Hydrogen Engine Combustion Concepts

- Hydrogen Engine Design

- Development of Hydrogen Injection Concepts

- Power Transmission Systems

- Generator Set System Design

- Gear System Design

- Development of Drive System Concepts

- Electronic Control Unit (ECU) Design and Development

- ECU Function Development and Calibration

- ECU Motor Integration and Commissioning

Infrastructure

- Software for IMM 1-Dimensional Modeling, Design, CFD, Vibration and Structural Analysis

- Datasets with more than 600 IMM Characteristics in a Wide Power Range

- V8 1,200 HP Original Engine BOM, Production Files and Assembly Instructions

- Parametric Engine Design

- Programmable Bosch MS 15.1 Electronic Control Unit

Turkish Automotive

Full Industrialization

At its center

R&D

Capabilities

Internal Combustion Engine Development and Mechanical Tests

Engine Subsystem Development and Tests

Internal Combustion Engine Performance and Emission Measurements

Vehicle Performance, Emission and Fuel Consumption Measurements

Internal Combustion Engine Performance and Emission Calibration

Internal Combustion Engine Modeling and Model Validation

Powertrain Development and Mechanical Tests

Development of Combustion Concepts and Injection Strategies

Control Unit Design and Development

R&D

How Can We Collaborate ?

Institutions

APPLIED R&D

APPLIED R&D

APPLIED R&D

APPLIED R&D

Project Based R&D Activities

- Private Sector R&D Projects

- Public Institutions R&D Projects

- TÜBİTAK ARDEB and TEYDEB Projects

- TÜBİTAK Bilateral/Multilateral Collaboration Projects

- European Union Projects

Consulting

TÜBİTAK RUTE Consultancy Services

Testing and Analysis

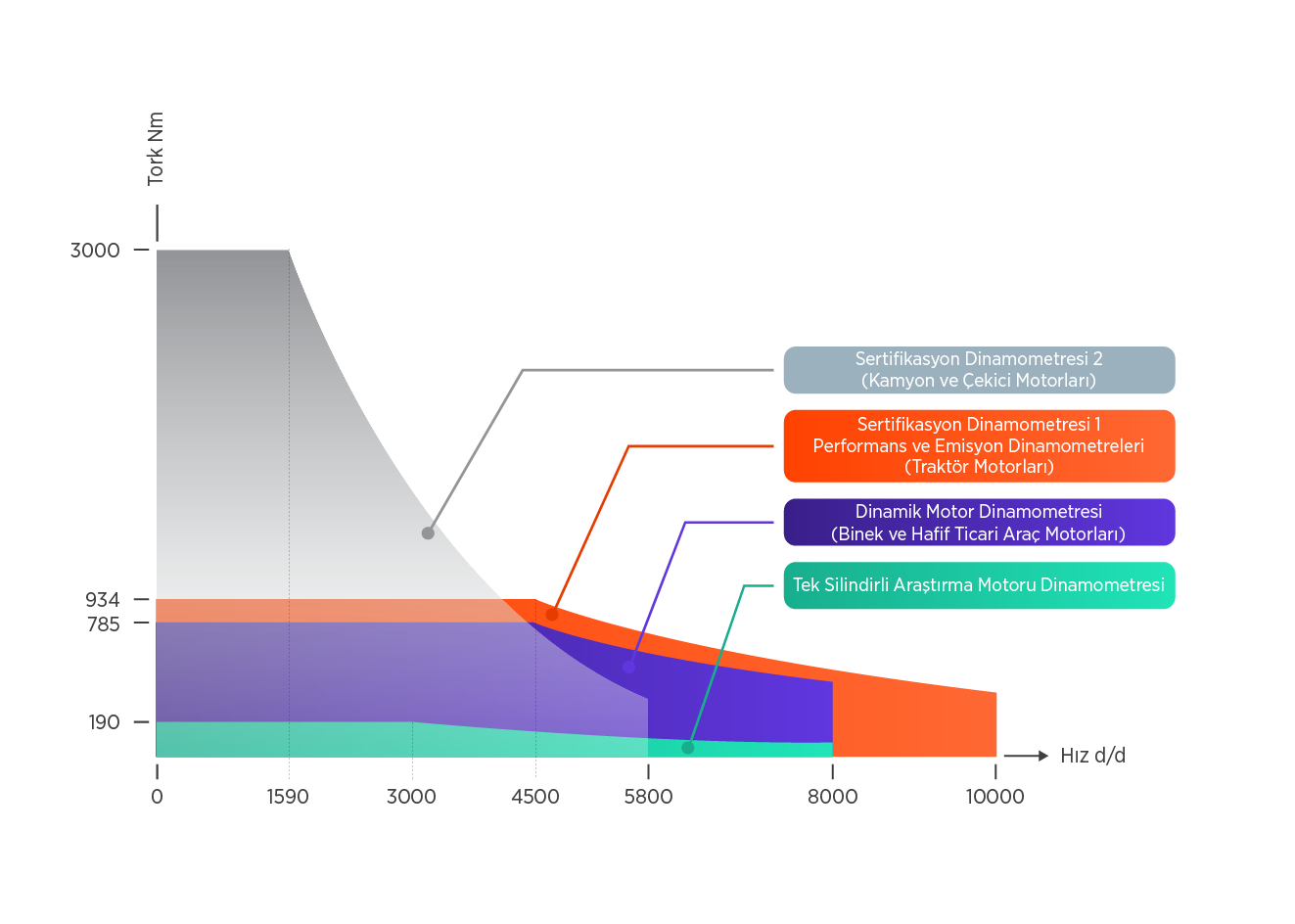

Dynamic Engine Dynamometer

Dynamometer

- Power: 370 kW

- Torque: 785 Nm

- Speed: 8,000 rpm

Equipments

- Fuel Consumption Measurement and Conditioning Device

- Combustion Air Conditioning Device

- Engine Cooling Water Conditioning Device

- Engine Oil Conditioning Device

- Blow By Measurement Device

- Soot Measurement Device

- Continuous Soot Measurement Device

- Continuous Emission Measurement Device

Capabilities

- Dynamic testing capability enabled by a low-inertia dynamometer

- Ability to work with original exhaust configurations due to the room's cross layout

- Combustion analysis with an in-cylinder pressure measurement system

- Calibration studies to meet Euro 6 emission limits

- Testing of numerous engine operating points with parameters automatically changed using an automation system

- Modification of engine operating parameters and testing of desired operating parameters with Bosch MS15.1 Diesel engine control unit

- Internal combustion engine R&D studies

Performance and Emission Dynamometers

Dynamometer 1 and 2

- Power 440 kW

- Torque: 934 Nm

- Speed 10,000 rpm

Equipments

- Fuel Consumption Measurement and Conditioning Device

- Combustion Air Conditioning Device

- Engine Cooling Water Conditioning Device

- Engine Oil Conditioning Device

- Blow By Measurement Device

- Soot Measurement Device

- Continuous Soot Measurement Device

- Continuous Emission Measurement Device

Capabilities

- Mechanical development and emission calibration of light commercial and off-road vehicle engines

- Combustion analysis with an in-cylinder pressure measurement system

- Calibration studies to meet Euro 6 emission limits

- Testing of numerous engine operating points with parameters automatically changed using an automation system

- Realistic simulation of complete powertrain and driver behaviors with high-dynamic torque control

- Internal combustion engine R&D studies

Certification Dynamometers

Dynamometer

- Power: 370 kW

- Torque: 785 Nm

- Speed: 8,000 rpm

Equipments

- Fuel Consumption Measurement and Conditioning Device

- Combustion Air Conditioning Device

- Engine Cooling Water Conditioning Device

- Engine Oil Conditioning Device

- Blow By Measurement Device

- Soot Measurement Device

- Continuous Soot Measurement Device

- Continuous Emission Measurement Device

Capabilities

- Dynamic testing capability enabled by a low-inertia dynamometer

- Ability to work with original exhaust configurations due to the room's cross layout

- Combustion analysis with an in-cylinder pressure measurement system

- Calibration studies to meet Euro 6 emission limits

- Testing of numerous engine operating points with parameters automatically changed using an automation system

- Modification of engine operating parameters and testing of desired operating parameters with Bosch MS15.1 Diesel engine control unit

- Internal combustion engine R&D studies

Single Cylinder Research Engines and Dynamometer

- High-speed camera imaging of in-cylinder combustion and spray events and combustion analysis

- Investigation of the effects of different spray strategies on combustion, performance and emissions

| Feature | TSAM for Gasoline Engines | TSAM for Diesel Engines of Light Commercial and Off-Road Vehicles |

|---|---|---|

| Cylinder Diameter | 65-100 mm [82 mm] | 75-110 mm [106 mm] |

| Cylinder Stroke | 60-95 mm [86 mm] | 80-130 mm [127 mm] |

| Sweeping Volume | 0.2-0.75 L [0.454 L] | 0.4-1.2 L [1.12 L] |

| Maximum Speed | 8,000 rpm [6,000 rpm] | 5,000 rpm [2,500 rpm] |

| Maximum Combustion Pressure | 150 bar [120 bar] | 210 bar [190 bar] |

Dynamometers and Covered Engines

Powertrain Dynamometer

Axle Dynamometer

- Power: 290 kW

- Torque: 4200 Nm

- Speed 3,000 rpm

Power Take-Off (PTO) Dynamometer

- Power: 160 kW

- Torque: 2,000 Nm

- Speed 3,000 rpm

Drive Dynamometer

- Power: 160 kW

- Torque: 2,000 Nm

- Speed 3,000 rpm

Equipments

- Transmission Oil Conditioning System

- Engine Coolant Conditioning System

- Robot Driver

- Gear Shifting Robots

Capabilities

- Configuration suitable for passenger cars and off-road vehicles

- Torque capacity of 35,000 Nm on front axle and 60,000 Nm on rear axle for off-road vehicle applications

- Maneuver and event-based simulation of real road driving behaviors in a laboratory environment

- Dynamic calculation of traction forces with 6 degree of freedom vehicle model

- Availability of different tire models that take slippage into account

- Dynamic driving cycle tests using robot drivers and gear-changing robots

Vehicle Performance and Emissions Dynamometer

48" 4WD Chassis Dynamometer

- Adjustable axle range between 2,100-4,700 mm

- Maximum speed of 250 km/h

- Maximum force of 14,400 N per axle

- Maximum power of 200 kW per axle

Equipments

- Raw and diluted emission measurement devices

- Pre-Cat, Post-Cat and EGR measurements

- Particle number measurement device

Climatic Chamber

- Temperature control from -10 °C to +40 °C

- ±1 °C temperature accuracy

- Humidity control from % 20 to % 95

- ±% 5 humidity accuracy

Capabilities

- Euro 6d (WLTP) compliant emission and fuel consumption measurement

- Euro 6d (WLTP) compliant energy consumption and range tests in hybrid and electric vehicles

- Simulation studies compatible with real road loads for 4x4 vehicle performance tests

- Cooling system performance tests at high and low temperatures